Fire water pumps boost the water pressure within facilities to provide adequate spraying power for fire suppression. They can draw from a public water supply, on-site water storage tank or a combination of both.

NFPA 20 requires that fire water pumps flow at least 150% of their rated flows. The designer should use a manufacturer’s performance curve to ensure this is achieved.

Horizontal Split Case

The horizontal split case pump is the workhorse of fire protection, providing water to stand pipe, sprinkler and hydrant systems. It is also used in wastewater treatment applications, industrial processes, cooling towers, and agriculture.

These pumps are a reliable and rugged type of centrifugal fire pump that is easy to maintain, as the casings can be easily opened without disturbing the driver or associated piping. They are available in a wide range of rated flow and pressure capacities, and can be powered by either electric or diesel motors.

These pumps are very sensitive to problems with the ring clearances that open up during operation, which can lead to poor alignment and bearing life. They must be inspected regularly by a qualified person and should not be subjected to excessive loads (i.e., horizontal elbows on the suction side of the pump). It is common for these pumps to be installed in the wrong orientation, which must be corrected before use.

Vertical Split Case

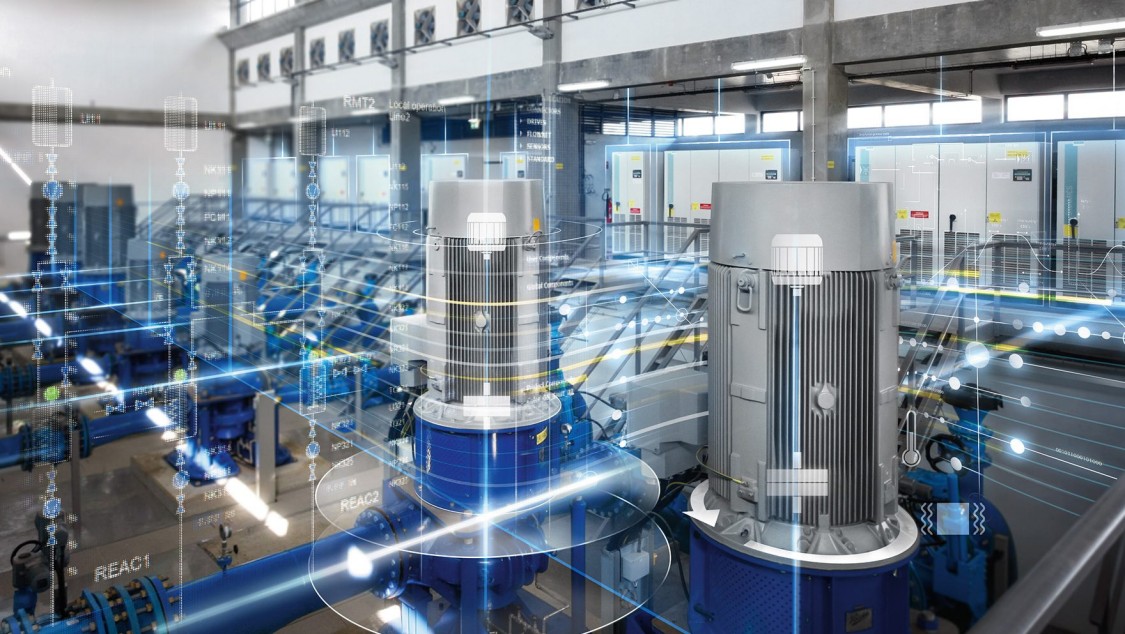

A vertical split case fire water pump is a great choice for smaller installations. These pumps have their motor shaft and pump shaft connected by a long coupling, which allows the pump head to be easily accessed without having to remove the entire motor. These pumps are easy to maintain, highly reliable and have a longer life span than other types of fire pumps.

Unlike end suction pumps, the discharge piping of a vertical in-line fire water pump can be perpendicular to the suction flange, which means less piping is required. However, this style of fire pump has a limited capacity up to 1,500 gpm (5,678 L/min), can only be used with an electric driver and is more susceptible to mechanical damage from water turbulence.

Fire pump standards require a stable and continuous decreasing Q-H curve to avoid cavitation which causes decreases in pressure and flow. A low NPSH-curve also helps to avoid the formation of vapor pockets in the pump, which can cause system failures.

Multi-Stage Pumps

When pressure is needed beyond that which can be created by a single impeller, multi-stage pumps are employed. These are centrifugal pumps with one or more impellers encapsulated in their own volute that form part of a common body. They can be operated in either a VOLUME (parallel) or PRESSURE (series) mode with a transfer valve at the first stage volute that allows water to enter all of the pump’s active impeller eyes in a common suction casing / diffuser and then exit from a common pump discharge.

The advantage of a multi-stage pump is that the operator can switch from the VOLUME to the PRESSURE mode with a simple change of engine throttle. This allows the pump to flow up to 70 percent of its rated capacity while generating the desired head at a lower engine speed than a single-stage fire pump. This means that pressure reducing valves (PRV) can be avoided, allowing the use of smaller sprinkler heads and saving on pipework costs and installation time.

Power Source

As with any fire protection system, the selection and installation of a fire water pump should be handled by certified fire safety professionals. The design of the electrical power systems that feed this vital equipment also requires special considerations. These are covered in the National Electric Code (NEC), NFPA 20, and local codes and standards.

The NEC requires a disconnecting means to be provided between the power source and the fire pump. This can be in the form of a switch, fuse, or circuit breaker. If the disconnect is used, it must be rated to allow the locked rotor current to flow without tripping.

If a single utility source is not reliable, multiple sources can be used, including on-site standby generators and combinations of services and generators. Conductors in the fire pump circuit must be sized to accommodate this load. The NEC has specific requirements relating to voltage drop and motor starting conditions, and requires that it be a maximum of 15% under both starting and running conditions.