Designed for drawing brass and mild steel tubes and bars. Features a hydraulic mandrel lifting and forward system, push pointer, and draw bench with discharging arms.

Horenco’s swaging, cold drawing and straightening machinery are top-of-the-line turnkey equipment that will make your manufacturing and fabricating jobs easier than ever. Click here to see their new line of equipment!

Bar-to-Bar

The cold drawing process improves the inherent machinability of many steel grades. This translates into easier chips to break, more parts produced per hour and longer tool life in high output NC and CNC equipment. It also reduces scrap and labor costs. It removes out-of-roundness that can strain collets and pushers, which means less downtime for repairs and maintenance. It also eliminates scale that can collect and work into moving segments of the machine causing premature part wear and shortening machine lifetime.

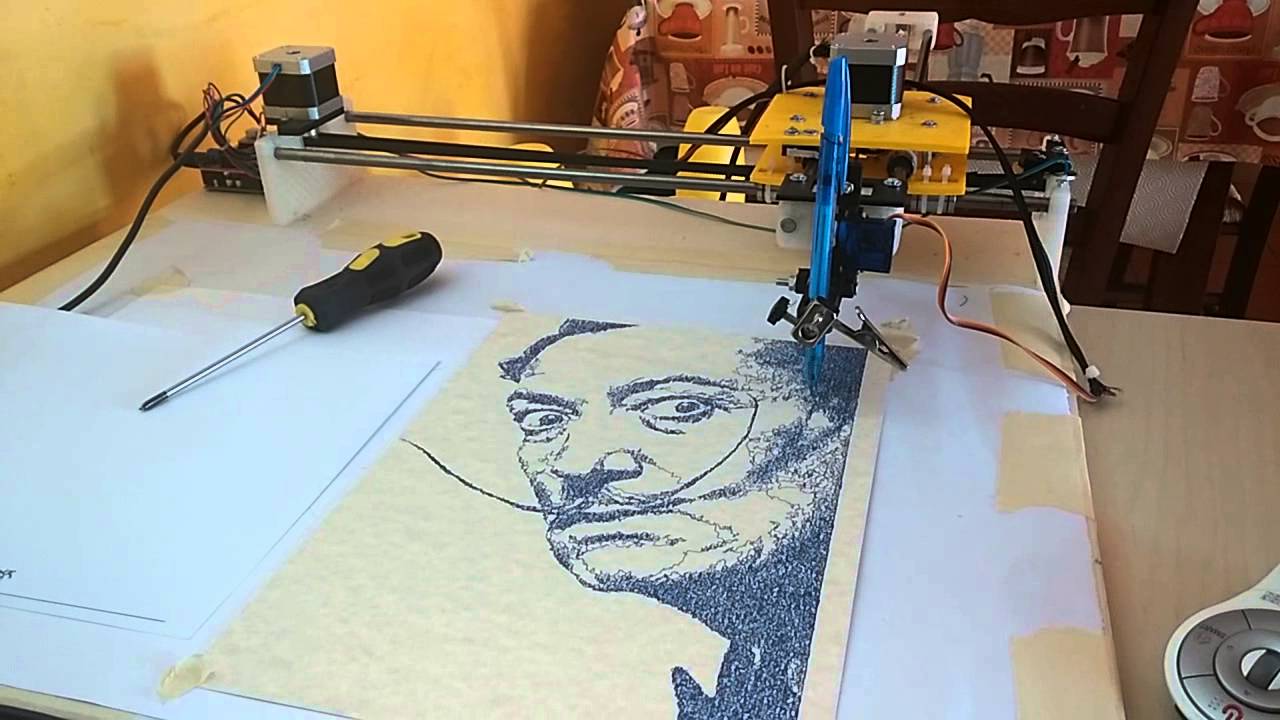

HOREN’s automatic chain-type Auto cold drawing machine are designed to streamline the precision drawing process with consideration to both size and tolerances. The HS model series is especially heavy-duty and uses a head-press mechanism to replace the swaging process that is normally required during traditional bar drawing. From loading to discharging the entire process is controlled using a PLC system making it highly efficient and ideal for bar-to-bar drawing. Typical applications include:

Head-Press

This type of machine has the drawing capstan affixed to the end of a main shaft, which also supports a flyer plate and sheaves. This design allows the machine to run in a continuous mode without having to rotate the capstan or sheaves after each drawing block. This design helps to minimize the natural wire twist that occurs in most draw machines.

The tilted-axis capstans of head-pressure machines help to direct the wire path from one sheave to the entry of the next die box. This reduces the number of sheaves and minimizes scratches on the wire package. The pivoting dancer rolls generate a small deflection of the wire path and accumulate speed information on the individual capstans, which allows quick and responsive control.

In the case of a dangerous emergency, a mechanical brake removes motor power to stop the machine immediately. A Norma stop slows the machine down to a moderate rate to provide maximum control and prevent damage to the wire package.

HS Model

The HS model series is designed to streamline the drawing process by using a hydraulically powered extrusion unit to clamp the stock piece and push it directly against the die. Brass, mild steel and alloy bars are typically drawn on this machine. The material is then carried through the drawbench using discharging arms to designated collection racks.

The machine uses a frequency inverter control to reduce energy consumption. It features a touch screen, a spraying tungsten carbide drum and an adjustable speed. It also has a wide range of takeup / payoff stands, including a static down coiler and a dual spooler.

In addition to the high-speed and low-energy design, this fine wire drawing machine uses a continuous annealing approach for elongation control. This eliminates the need for traditional AC voltage annealing, saving energy by up to 35% and cutting costs by up to 40%. The system can be used to produce construction wire, galvanized wire, spring wire, steel core wire and welding wire.

SA Model

Bersel Makine provides first class straight line wire drawing machines to our customers with years of experience. These machines are designed for either straight or deflection free drawing of low or high carbon steel wires. They are easy to install and can be modified according to production line requirements. They use inverter speed controlled motor and rotating roller are water cooled for synchronization. The wire drawing blocks are Tungsten Carbur coated to avoid frictional contact between metal and machine.

The process is similar to bar drawing except that the starting stock is a tube instead of a flat piece of metal. The reduced end of the tube passes through a die opening and is drawn to decrease its diameter, shape its profile, improve surface finish, and increase dimensional accuracy. The material is usually annealed before, during (between draws), or after drawing to increase its ductility and remove internal stresses.

The drawing line consists of attitude wire discharging rack, SSS-LZ6-560 straight type wire drawing machine, 800 H-type spool wire winding machine and control cabinet and operating floor. The system is equipped with frequency converter and PLC to control the electric apparatus.